As the world is advancing, the need for more precise measurements has increased. Some companies are using a camera for defect detection. A vision measuring system includes a camera, a light source, and smart detection software. This setup has transformed the parameters.

Manufacturers use the system to measure dimensions and defects without needing the equipment. It is an advanced measurement method with high precision, which is required nowadays.

In this article, you will get information about the things that you can measure by using VMS.

How a Vision Measuring System Works?

The vision measuring system works by using a camera. It controls the lighting and runs software to create images. After that, the engineers will identify the defects from the pictures.

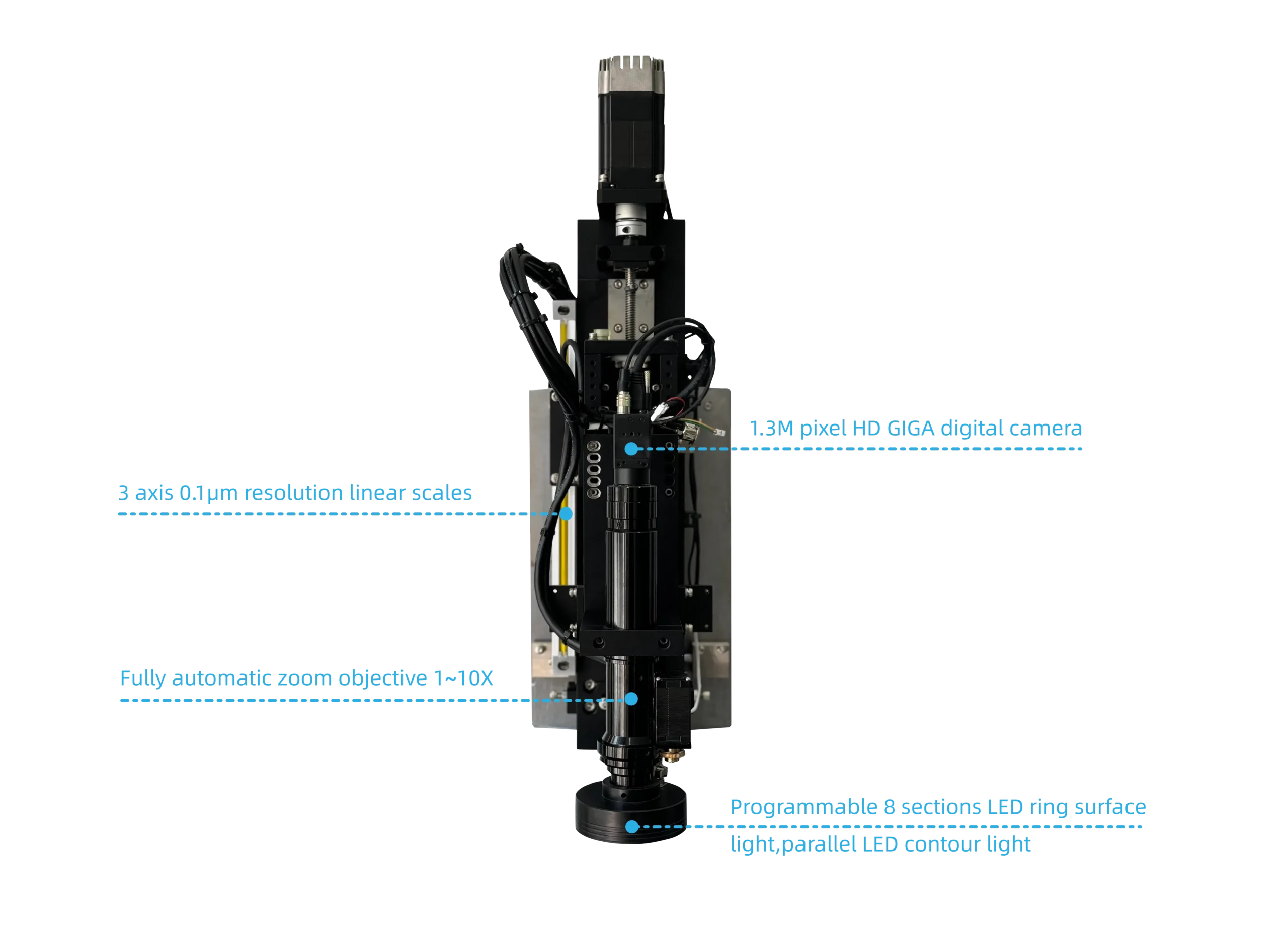

– In industries, manufacturers use high-resolution cameras. These cameras have a resolution of about 4 MP to 8 MP to capture images.

– To capture images of the components, a constant light supply is necessary.

– The AI software uses smart algorithms to check the shape, size, color, and alignment of the parts.

– After gathering the data, the manufacturer checks for differences or flaws. They compare it to preset standards.

The system includes a feature that detects faulty parts in the production line. When it identifies a problem, production halts.

Vision Measuring Systems and Its Accomplishments

The use of Vision Measuring has transformed defect detection across many industries. The features you can accomplish are detailed here.

– A vision measuring system helps you spot defects in measurements and dimensions faster and more accurately.

· VSM measures the fragile product without touching it, which the user prefers.

Manufacturers use VSM to ensure product quality in industries that meet measurement goals. The measurement for every equipment remains the same.

– This vision measuring system can measure 2D and 3D dimensions of products, with some changes.

· You can record data in the software. Then, compare the results to the manufacturers’ standards.

Industrial Applications

The use of vision-measuring systems is widespread across many sectors. Some of the industry-specific applications of the system are as follows:

Automotive Industry

· The system is widely used to find defects in engine parts, gears, and pistons. This ensures they function properly.

· Sometimes, the surface of automobiles gets scratches. You can find these scratches using a vision measuring system.

Aerospace industry

– Manufacturers can find defects or deformities in the airshaft and blades with a vision measuring system.

· The accurate size of the different parts of an aircraft is maintained by using VSM.

Electronics

· The circuit boards in electronic devices are typically printed circuit boards. Any differences from the standard are found using VSM.

· The diode and resistor placement on the circuit board is accomplished by using VSM.

Medical industry

· The use of instruments in the medical industry must have accurate dimensions. Using VSM facilitates the reproducible production of identical medical devices with precise dimensions.

Conclusion

To summarize, vision-measuring systems have significantly improved inspection accuracy in modern industries.

· These systems guarantee precise, non-contact evaluation of complicated parts.

· It uses high-resolution imaging, controlled lighting, and intelligent software.

· Their dimensions, geometry, and surface quality provide reliable product specifications.

Many industries rely on VMS technology to spot tiny defects in a range of equipment. Such as:

· Automotive and aerospace industries

· Electronic device detection

· Geometry of automotive and aerospace components

These devices provide greater efficiency, repeatability, and quality assurance. Vision measuring systems are vital for making high-quality products and staying competitive.

Learn more about features of MXP Vision Measuring Machine