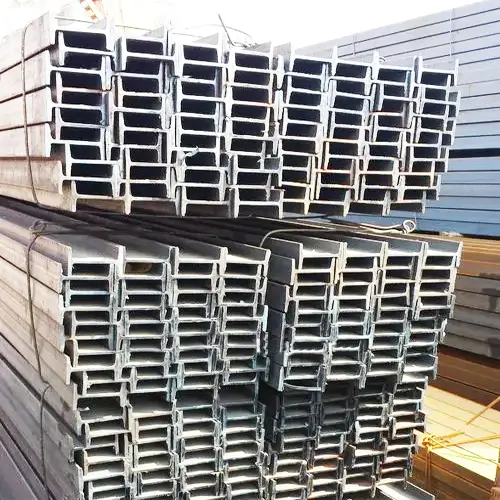

H-shaped steel is a cost-effective profile. Its shape resembles the capital letter H. It’s also known as a universal steel beam, wide edge I-beam, or parallel flange I-beam. The cross section of H-shaped steel usually includes two parts: web and flange plate, also known as waist and edge.

H-beam Steel Production Method

Manufacturers produce H-shaped steel by welding or rolling. To weld H-shaped steel, cut strip steel to the right thickness and width. Then, use a continuous welding unit to join the flange and web together. Welding H-shaped steel has some downsides: it uses a lot of metal, quality can vary, and size choices are limited. Thus, the production of H-shaped steel primarily involves the rolling method. In modern steel rolling production, universal rolling mills are used to roll H-shaped steel. The web of the H-shaped steel rolls between the upper and lower horizontal rollers. At the same time, the flange rolls between the sides of the horizontal rollers and the vertical rollers. The universal rolling mill can’t press down the flange edge alone. So, an edge rolling machine, also called a flange rolling machine, must be set up behind it. This machine presses down the flange edge and controls the flange width. . In the rolling operation, the two stands work together. They make the rolled piece pass back and forth several times (see Figure 2a). Alternatively, the rolled piece can go through several universal stands and one or two edge rolling end stands. The continuous rolling mill group reduces the material in each pass. This process shapes the blank into products with specific sizes and specifications.

In the flange area of the rolled piece, the horizontal roller slides against it. This causes significant wear on the roll. To help the rolls regain their shape after heavy rolling, tilt the roughing mill unit’s upper and lower horizontal rolls at an angle between 3° and 8°. The same goes for the vertical roll surfaces. To fix the inclination angle of the finished product flange, we set up a universal rolling mill. This mill is also known as a universal finishing mill. The side of the horizontal roll is either perpendicular to its axis or has a slight incline, usually no more than 20 degrees. The vertical roll is cylindrical.

H-beam steel Representing Method

H-shaped steel has three types:

-

Wide-flange H-shaped steel (HK)

-

Narrow-flange H-shaped steel (HZ)

-

H-shaped steel column (HU)

The expression method is: height Hx width Bx web thickness t1x wing plate thickness t2. For example, H-shaped steel Q235\SS400: 200x200x8x12 means it has a height of 200mm and a width of 200mm. The web thickness is 8mm, and the wing plate thickness is 12mm. The grade is Q235 or SS400.

Advantages of Hot Rolled carbon steel materials

1. Hot-rolled H-shaped steel structures are highly manufactured. They are great for mechanical work and intensive production. These structures offer high precision, easy installation, and consistent quality.

2. The project is built quickly. It covers a small area. It works well in all weather and is less impacted by climate.

3.Increase the effective use area of the structure

4. Compared to welding H-shaped steel, this method saves labor and materials. It cuts down on raw material, energy, and labor use. It also results in low residual stress and offers a great appearance and surface quality.

5.Facilitates machining, structural connection and installation. Also easy to dismantle and reuse.