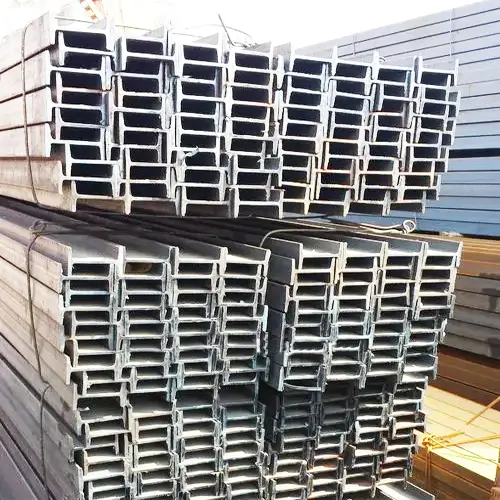

An cheap cross-section profile looks like the letter H. It is also known as a universal steel beam, wide edge I-beam, or parallel flange I-beam.

The cross-section of H-shaped steel usually includes two parts: web and flange plate, also known as waist and edge.

Features:

The inner and outer sides of H-shaped steel flanges are parallel or nearly so. The flange ends form right angles, which is why it’s called a parallel flange I-beam. The web thickness of H-shaped steel is thinner than that of regular I-beams with the same web height. However, its flange width is wider than that of regular I-beams of the same height. Because of this, it is often called a wide-edge I-beam. H-shaped steel has a better section modulus, moment of inertia, and strength than regular I-beams of the same weight. This advantage comes from its shape. It excels in metal structures with various needs. It performs well under bending moments, pressure loads, and eccentric loads. It can greatly increase the load-bearing capacity compared with ordinary I-beams and save 10% to 40% of metal. H-shaped steel has wide flanges, thin webs, multiple specifications, and flexible use. It can save 15% to 20% of metal when used in various truss structures. The flange has parallel inner and outer sides, with edge ends at right angles. This design makes it easy to assemble into different components. As a result, it saves about 25% on welding and riveting. This can speed up construction and shorten project timelines.

Classification

There are many product specifications of H-shaped steel, and the classification methods are as follows. (1) The flange width of the product divides it into wide flange, medium flange, and narrow flange H-shaped steel.

In wide-flange and medium-flange H-shaped steel, the flange width B is at least as wide as the web height H.

In narrow-flange H-shaped steel, the flange width B is roughly half the web height H.

Also, based on their use, H-shaped steel is classified into:

-

H-shaped steel beams

-

H-shaped steel columns

-

H-shaped steel piles

-

Extremely thick flange H-shaped steel beams

Sometimes parallel leg channel steel and parallel flange T-shaped steel are also included in the scope of H-shaped steel. Engineers typically use narrow-flange H-shaped steel for beams, while they use wide-flange H-shaped steel for columns. Accordingly, it is also called beam-type H-shaped steel and column-type H-shaped steel. (3) According to the production method, it is divided into welded H-shaped steel and rolled H-shaped steel. (4) According to the size, it is divided into large, medium, and small H-shaped steel. Products with a web height (H) above 700 mm are large. Those between 300 mm and 700 mm are medium. Products with a web height less than 300 mm are small. By the end of 1990, the world’s largest H-shaped steel web had a height of 1200 mm and a flange width of 530 mm.

Advantages of Hot-Rolled H-Beam

-

Steel structures made from hot-rolled H-shaped steel are highly manufactured. They allow for easy mechanical production and installation. This method ensures high precision and quality, making it very convenient. They can be made into factories for building houses, bridges, industrial plants, and more.

-

The project has a fast construction speed. It covers a small area and is suitable for all-weather work. This means it is less affected by climate conditions.

-

Increase the effective use area of the structure.

-

Using H-shaped steel instead of welding saves on labor and materials. It cuts down on raw materials, energy, and labor use. Plus, it results in low residual stress and offers great appearance and surface quality.

-

Facilitates machining, structural connection, and installation. Also, it is easy to dismantle and reuse.