ASTM A240 321 310S 309S 430 2b/Ba/8K/Mirror/Embossed/Checkered Stainless Steel Plate

Stainless steel plates resist corrosion from weak media like air, steam, and water. Acid-resistant steel plates can resist corrosion from strong chemicals. This includes acids, alkalis, and salts. The stainless steel plate has a smooth surface. It offers plasticity, toughness, and mechanical strength. Plus, it resists corrosion from acids, alkaline gases, solutions, and other substances. It is an alloy steel that is prone to rust, but is not absolutely rust-free.

Performance

– **Corrosion Resistance**: Stainless steel plates resist corrosion well. However, the nickel-chromium alloy 304 is less stable. Prolonged heating in the temperature range of chromium carbide levels may affect alloys 321 and 347 in harsh corrosive media. These materials resist sensitization, making them suitable for high-temperature applications. This helps prevent intergranular corrosion, even at lower temperatures.

– High-temperature oxidation resistance: Stainless steel plates resist oxidation at high temperatures. But their oxidation rate depends on factors like the environment and product form.

– **Physical Properties**: The overall heat transfer coefficient of a metal relies on more than just its thermal conductivity. In most cases, the heat dissipation coefficient of the film, rust scale, and surface condition of the metal are important. Stainless steel stays clean. It also conducts heat better than metals with higher thermal conductivities. The flame of oxygen plus gas cannot cut stainless steel plates because stainless steel resists oxidation.

Elemental effects – Carbon (C): 1. Improve the blade’s resistance to deformation and tensile strength; 2. Enhance its hardness and improve its wear resistance. – Chromium (Cr): 1. Enhances hardness, tensile strength, and toughness; 2. Prevents wear and corrosion. – Cobalt (Co): 1. Increases hardness and strength so that it can withstand high-temperature quenching; 2. Used in more complex alloys to strengthen certain individual properties of other elements. – Copper (Cu): 1. Enhances corrosion resistance; 2. Enhances wear resistance. – Manganese (Mn): 1. Increases hardenability, wear resistance, and tensile strength; 2. Takes away oxygen from the molten metal through separated oxidation and separated vaporization; 3. When added in large amounts, it enhances hardness but increases brittleness. – Molybdenum (Mo): 1. Enhances strength, hardness, hardenability, and toughness; 2. Improves machinability and corrosion resistance. – Nickel (Ni): 1. Enhances strength, hardness, and corrosion resistance. – Phosphorus (P): Enhances strength, machinability, and hardness.

Thickness

- Thin plate: 0.2 mm to 4 mm

- Medium plate: 4 mm to 20 mm

- Thick plate: 20 mm to 60 mm

- Extra thick plate: 60 mm to 115 mm

Production Method

(1) Hot-rolled steel plate (2) Cold-rolled steel plate

Surface features

- O.1, Silver white, matt, hot rolled to specified thickness.

- NO.2D is silvery white. It is heat-treated and pickled after cold rolling. It is used for deep drawing.

- NO.2B, Glossier than NO.2D. After NO.2D treatment, the final light cold rolling is carried out through polishing rollers.

- BA, as bright as a mirror. There is no standard, but it is usually a bright annealed surface finish with a very reflective surface. Building materials, kitchen utensils.

- NO. 3, Coarse grinding

- NO. 4, Intermediate grinding

- NO. 240, Fine grinding

- NO. 320, Extremely fine grinding

- NO. 400, Gloss close to BA

- HL, Building and construction materials

- NO.7, Mirror grinding

- NO. 8, Mirror grinding

Related products

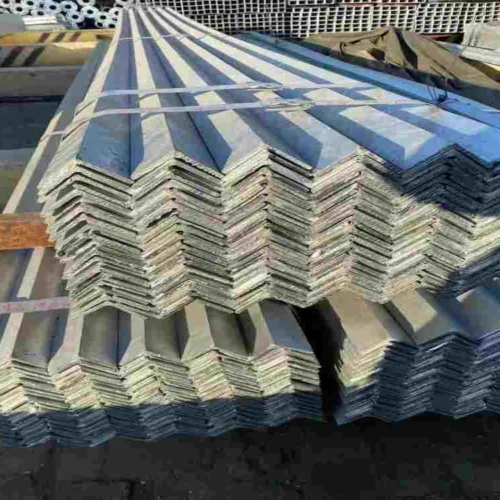

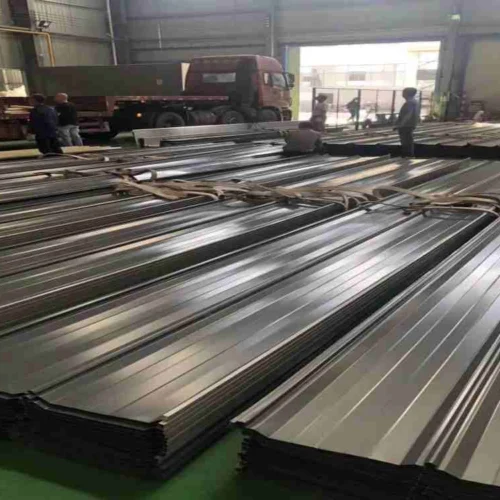

Stainless Steel Corrugated

Stainless Steel