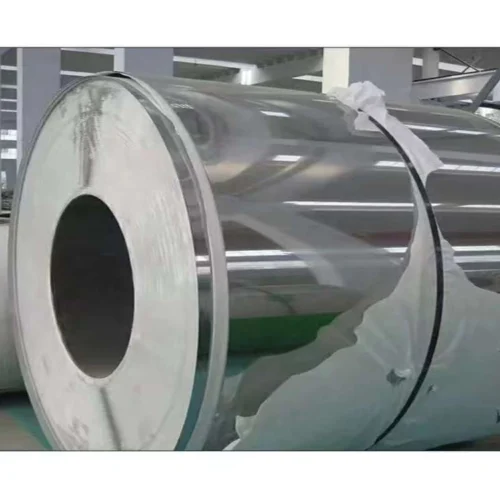

Quality Stainless Steel Cooling Coil 304 201 316 430 Cold Rolled 2B Surface

Stainless steel contains at least 10.5% chromium and no more than 1.2% carbon. This is according to GB/T20878-2007.

The corrosion resistance of stainless steel decreases with the increase of carbon content. Therefore, the carbon content of most stainless steel is low, with a maximum of no more than 1.2%. The ωc (carbon content) of some steels is even lower than 0.03% (such as 00Cr12 ). The main alloying element in stainless steel is Cr (chromium). Only when the Cr content reaches a certain value, the steel has corrosion resistance. Therefore, stainless steel generally has a Cr (chromium) content of at least 10.5%. Stainless steel also contains Ni, Ti, Mn, N, Nb, Mo, Si, Cu and other elements. Stainless steel is a type of steel that resists weak corrosion. This includes exposure to air, steam, and water. Acid-resistant steel is a steel that resists corrosion from acids, alkalis, and salts.

The two have different chemical compositions, so their corrosion resistance varies. Ordinary stainless steel usually corrodes when exposed to chemicals. In contrast, acid-resistant steel is typically stainless. “Stainless steel” workpieces include over one hundred types of stainless steel. Each type is designed for specific applications and performs well in its field. There are usually only six types of steel relevant to building construction applications. They all contain 17 to 22% chromium, and the better steel types also contain nickel. Adding molybdenum can further improve atmospheric corrosion, especially corrosion resistance in chloride-containing atmospheres. Stainless steel is harder than regular aluminum alloy. It also costs more than aluminum alloy.

Main type: Stainless steel has five main categories based on its structure:

-

Martensitic steel

-

Ferritic steel

-

Austenitic steel

-

Austenitic-ferritic (duplex) stainless steel

-

Precipitation hardening stainless steel

Stainless steel can also be divided by its composition. This includes:

-

Chromium stainless steel

-

Chromium-nickel stainless steel

-

Chromium-manganese-nitrogen stainless steel

There’s also a special stainless steel for pressure vessels. It’s called “GB24511_2009_Stainless steel plates and steel strips for pressure-bearing equipment.

The composition divides into several series:

-

Cr series (400 series)

-

Cr-Ni series (300 series)

-

Cr-Mn-Ni series (200 series)

-

Heat-resistant chromium alloy steel (500 series)

-

Precipitation hardening series (600 series)

200 Series: Chromium-Manganese-Nickel

201, 202, etc.: Nickel is replaced by manganese, which has poor corrosion resistance and is widely used as a cheap substitute for the 300 series in China.

300 Series: Chromium-Nickel Austenitic Stainless Steel

304: Universal model; i.e. 18/8 stainless steel. Products such as: corrosion-resistant containers, tableware, furniture, railings, and medical equipment. The standard composition is 18% chromium plus 8% nickel. It’s a non-magnetic stainless steel. Heat treatment won’t change its metallographic structure. The GB grade is 06Cr19Ni10.

304 L: Similar to 304, but with low carbon. This makes it more resistant to corrosion and easier to heat treat. However, it has poor mechanical properties. It’s good for welding and products that are hard to heat treat.

309 S: It has a lot of chromium and nickel, so it has good heat resistance and oxidation resistance. Products such as: heat exchangers, boiler components, and jet engines.

310: Excellent high-temperature oxidation resistance, maximum use temperature 1200℃.

316: After 304, the next most popular steel grade is mostly used in the food industry, watch parts, pharmaceuticals, and surgical tools. Adding the molybdenum element makes it obtain a special corrosion-resistant structure. Because it has better resistance to chloride corrosion than 304, it is also used as “marine steel”. SS316 is usually used in nuclear fuel recovery devices. Grade 18/10 stainless steel is also generally suitable for this application level.

316 L: Low carbon, so it is more corrosion-resistant and easy to heat treat. Products such as: chemical processing equipment, nuclear power generators, and refrigerant storage tanks.

321: In addition to reducing the risk of material weld corrosion due to the addition of titanium, other properties are similar to 304.

400 series: ferritic and martensitic stainless steel, no manganese, can replace 304 stainless steel to a certain extent.

430: Ferritic stainless steel, for decoration, such as for automotive accessories. Good formability, but poor temperature resistance and corrosion resistance.

500 Series: Heat-resistant chromium alloy steel. 600 Series: Martensitic precipitation-hardening stainless steel.

Stainless steel surface processing grade

NO.1 The process subjects the surface to heat treatment and pickling treatment after hot rolling. Generally used for cold-rolled materials.

-Blunt surface: NO.2D, which has been heat-treated and pickled after cold rolling. The material is soft and the surface is silvery white. It is used for deep stamping processing.

-Matt surface: NO.2B After cold rolling, it is heat treated, pickled, and then finished rolled to make the surface moderately bright.

-Coarse grit NO.3 is a product ground with a No. 100-120 grinding belt. It has better gloss and discontinuous rough lines

-HAIRLINE: HLNO.4 is made using a polishing belt with a specific particle size. This creates a unique grinding pattern through continuous grinding. It is mainly used for architectural decoration.

– Bright surface: BA is made by cold rolling, bright annealing, and smoothing. The surface has good gloss and high reflectivity, like a mirror.

Related products

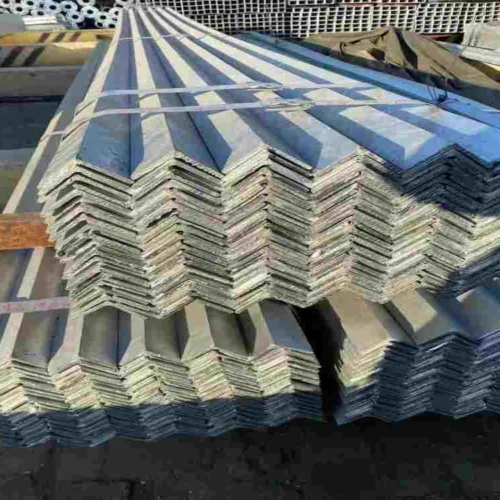

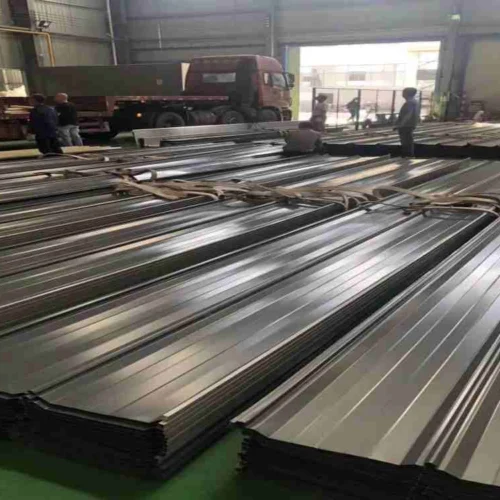

Stainless Steel Corrugated

Stainless Steel